Grain Drying Systems

Manufactured for Energy Efficiency: Some of the air in the cooling section is mixed with hot air, thus circulating the air inside the dryer. Thus, fuel economy is provided. Especially in cold outdoor temperatures, the energy efficiency that occurs is high.

Suitable for all grains: Since the grains are away from the combustion chamber during drying, these types of dryers are recommended for all grains, especially oilseeds.

Drying can be done using a wide variety of fuels. With a separate boiler design for each fuel, coal, wood, rice husk, sunflower husk, natural gas, diesel, LPG, biogas, fuel oil, any biomass can be used as fuel in this dryer.

Manufactured to dry without damaging the grain: Thanks to the low grain temperature;

Grain properties are minimally affected.

Thanks to the superior design of the mixed flow dryer, the grain never reaches a high grain temperature inside the dryer.

High grain temperature reduces the protein content of grains used as feed raw materials and increases grain breakage. Surface cracks increase especially in rice and corn. It causes the inner part of the grain to shrink. It reduces flour yield in dry milling and starch ratio in wet milling. It reduces oil quality and yield in oil seeds. It reduces the baking quality of wheat.

High grain temperature also affects seed yield by reducing germination value.

Homogeneous and uniform drying: Thanks to its superior design,

Each grain in the dryer encounters the drying air equally.

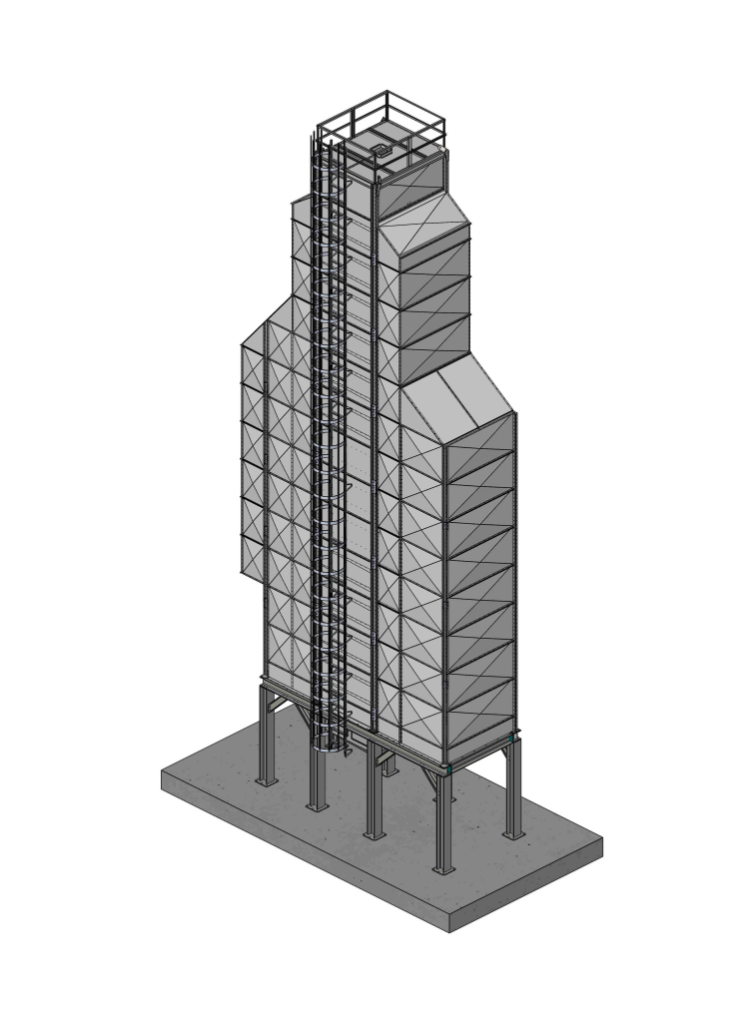

Thanks to the numerous V channels in the drying tower, the grain is mixed repeatedly as it descends from the drying tower.

Drying is not done by first heating and then cooling, but by both heating and cooling at the same time. Thus, the grain grain temperature does not increase in a way that will cause yield loss.

Since there is no grain exposed to hot air more or less than others, homogeneous drying is achieved on a grain and product basis.

Technical Specifications

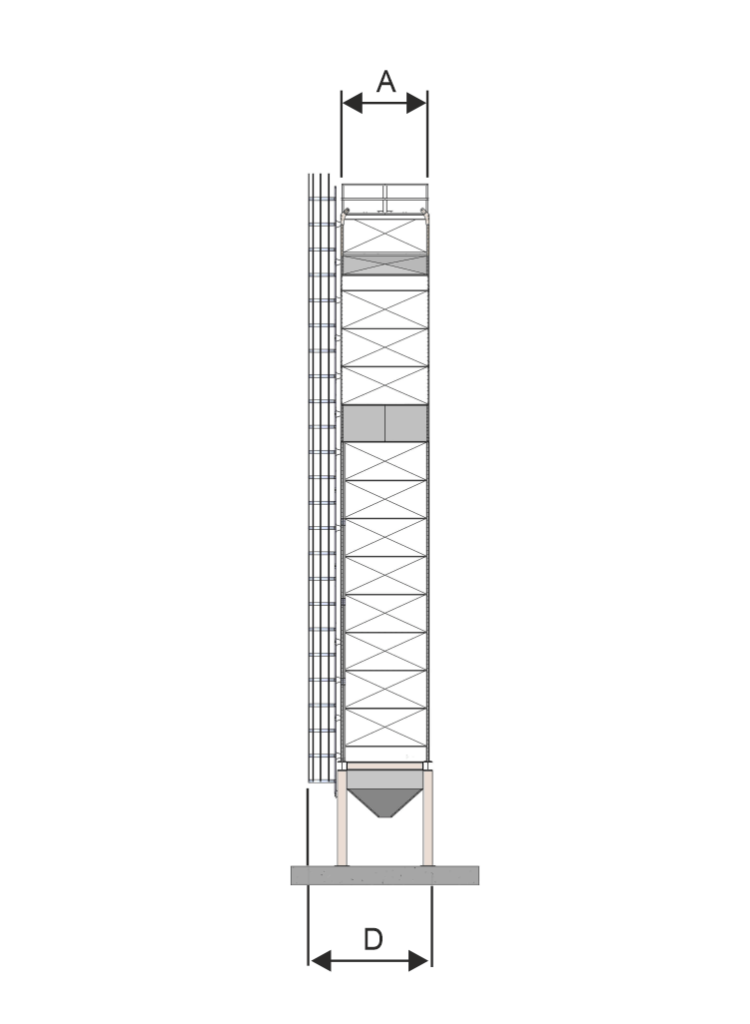

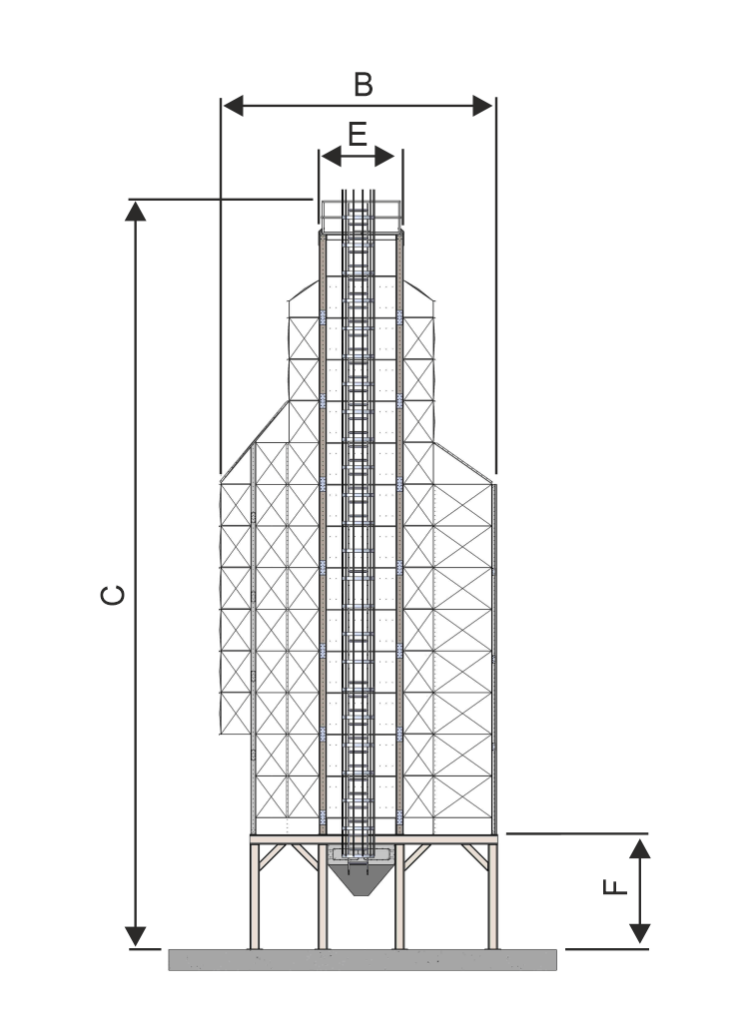

| CAPACITY TON / S | A (m) | B (m) | C (m) | D (m) | E (m) | F (m) |

|---|---|---|---|---|---|---|

| 15 | 2,35 | 6,6 | 14,8 | 3,4 | 2 | 2,75 |

| 20 | 2,35 | 6,6 | 16,8 | 3,4 | 2 | 2,75 |

| 25 | 2,35 | 6,6 | 19,5 | 3,4 | 2 | 2,75 |

| 35 | 4,5 | 6,6 | 19,5 | 5,6 | 2 | 2,75 |

| 50 | 4,5 | 7,25 | 19,5 | 5,6 | 2 | 2,75 |

| 75 | 6,7 | 7,25 | 19,5 | 7,7 | 2 | 3,55 |

| 100 | 6,7 | 7,25 | 26,5 | 7,7 | 2 | 3,55 |